Pneumatic Hydraulic Automatic Laminating and Coating Machine for

High - grade Cardboard

Product Use:

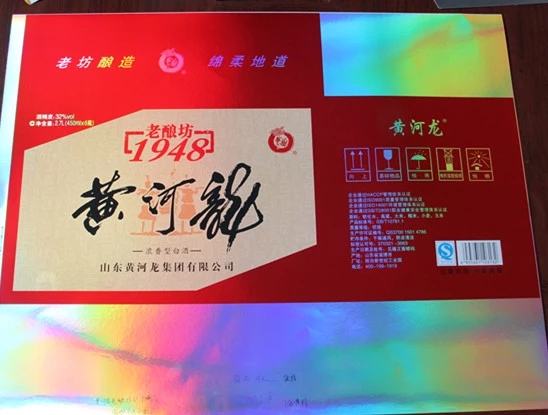

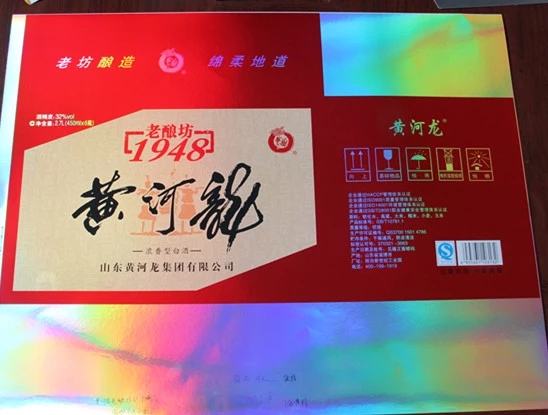

Model ZNFH1300 Laminating Machine, developed by Chinese Leading Manufacturer of

packaging. For coating or lamination of the roll paper with aluminum foil ,

PET, OPP, laser film, aluminum plated film, Rainbow film etc. Products are widely used in tobacco, alcohol,

gifts, toys and other high-grade internal and external packaging.

The following main features make the machine one of the most

popular laminator models in the markets. It adopts computerized PLC control, Low

labor intensity, stable performance, humanized operation, energy

saving.

Advanced machine control system, reasonable structure,

well-equipped, good looks, high degree of automation, stable

performance, leading to similar equipments in China, the superior

cost performance is undoubtedly the ideal choice for equipment of

similar products.

Parameters:

| 1 | Max.unwinding diameters | Φ1500mm |

| 2 | Laminating width | 600-1200mm |

| 3 | Paper core diameters | 3″,6″,12″ |

| 4 | Laminating Film Max.Diameter | 3″ |

| 5 | Film Unwinding Core | 3″ |

| 6 | Max.Diameter Rewinding Roller | φ1500mm |

| 7 | Rewinding Core | 12 |

| 8 | Roller Width | 1300mm |

| 9 | Paper thickness | 40~400gsm |

| 10 | Film material thickness | 0.001~0.06mm |

| 11 | Heating oven | 12.5mm |

| 12 | Max.speed | 120m/min |

| 13 | Total power | 112kw |

| 14 | Overall dimension | 22.5x2.8x3.2m |

1. Paper unwinding unit

Full set of hydraulic shaftless unwinding system, with 1 piece of

Hydraulic motor pump station, pieces of Magnetic brakes of 100 Nm,

Overall up, down, left, right, clamping, release, six movements

accurate.

2. film unwinding unit

Adjustable unwinding mechanism, 50 Nm magnetic brakes, digital

unwinding tension control

3. Gluing application unit

Using the transfer type two steel two plastic rollers, and configure pneumatic control pressure roller,measuring the amount of plastic twice, to make sure pressure is

adjustable and the glue evenly,

4. Color (coating) unit

Pneumatic control imprint, Precision anilox coating or printing,

Roller easy loading and unloading, horizontal reciprocating

squeegee and configure automatic solvent recycling equipment.

5. Lamination and calendaring unit

Pressure Control Precision lamination rollers, andφ150mm Top mirror

lamination steel roller

6. Drying tunnel

12.5 m average uniform temperature drying tunnel, four segments

temperature zone, pneumatic open built-in independent temperature

zone climate control, configuration, four sets of external and

efficient electric heating hot air system, two sets of out hot air

damper adjusting device and two sets of reuse system

7. Cooling recovery calendar traction unit

Supercharged air pressure control precision rubber roller nip and

efficient cooling with built-in circulation top φ320 mm S-type

double-sided mirror roll cooling recovery. Additional compulsory

paper surface temperature cold treatment

8. Synchronization Control

Realize the whole frequency PLC-speed automatic synchronization

control. Two random "Start Stop. Accelerated slowdown."

9. Rewinding unit

Center of the surface combined with pressure arm winding, variable

frequency motor automatic tension control system, hydraulic

automatic unloading.

10. Low-voltage electrical components used brand-name electrical

products

11. Electrical Control System

Adopts PLC centralized control, stable performance.